Forskelle på

SLS, SLA og FDM-print

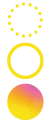

SLS-print

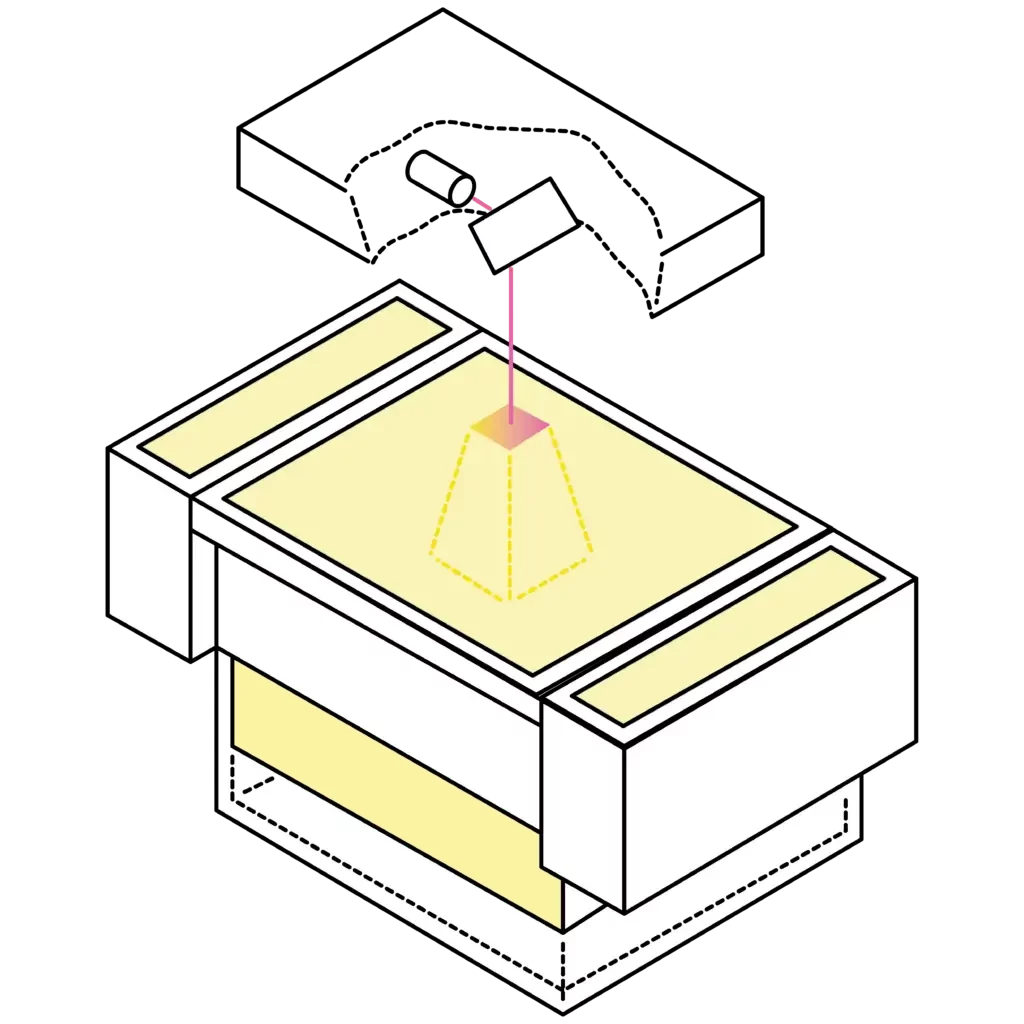

SLA-print

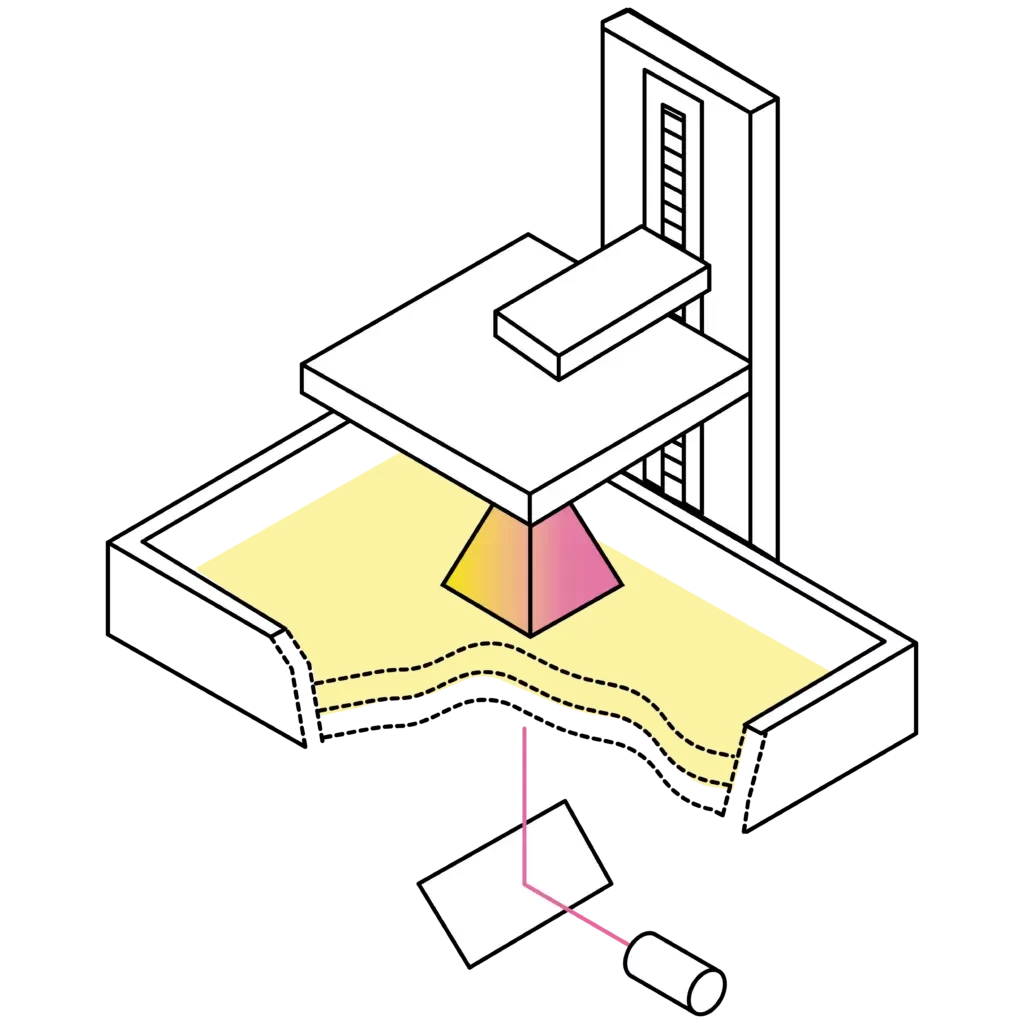

FDM-print

Differences in 3D printing technologies

SLS | SLA | FDM | |

|---|---|---|---|

Advantages | SLS printing has strong functional parts

With SLS printing, there is great design freedom There is no need for support structures in SLS printing SLS printing achieves a good finish and therefore has a visually attractive appearance” | SLA printing has high accuracy

SLA printing has a smooth surface finish SLA printing has a range of functional applications | FDM printing involves low-cost consumer machines and materials

FDM printing is quick and easy for simple, small parts |

Disadvantages | SLS printing has a rough surface finish.

SLS printing is limited in material selection. | SLA printing is sensitive to prolonged exposure to UV light. | FDM printing has low accuracy.

FDM printing is limited to low-level details. FDM printing has limited design compatibility. |

Applications | SLS printing is used for functional prototyping.

Low volume manufacturing, bridge manufacturing, or custom manufacturing. | SLA printing is used for functional prototyping.

Patterns, molds, and tooling. Dental applications. Prototyping. Model making. |

FDM printing is used for low-cost rapid prototyping.

FDM printing is used for basic proof-of-concept models. |

Material | SLS printing is made with engineering thermoplastics such as Nylon 11, Nylon 12, and Nylon GF30. | SLA printing is done using variants of resin (thermosetting plastic).

Standard, engineering (ABS-like, PP-like, flexible, heat-resistant), castable, dental, and medical (biocompatible). | FDM printing is done using standard thermoplastics such as ABS, PLA, and their various blends. |

Price level | Medium | Expensive | Cheap |